Making Industrial Automation Wireless

Enabling Your Machines & Production Lines to Do More

Get a Demo

Watch Video

Enabling Adaptive & Flexible Packaging Machines

Reduced Changeover Time, Multiple Product & Package Variations, Reduced Footprint

Watch Video

Get a Demo

Factory-Wide Connectivity Solutions

CoreTigo’s solution addresses a variety of industries, such as automotive, food & beverage, pharmaceuticals, metalworks, and more. These solutions drive operational efficiency, production optimization, higher availability, and greater intelligence to manage the business.

Enabling Adaptive and High-Performance Manufacturing

Machine Builders, Automation Equipment Manufacturers, System Integrators, and Manufacturing Facilities are harnessing CoreTigo’s wireless and machine optimization solutions to increase flexibility, adaptivity, and capacity while improving operational efficiency and sustainability.

- Machine Builders

- Automation Manufacturers

- System Integrators

- Manufacturing Facilities

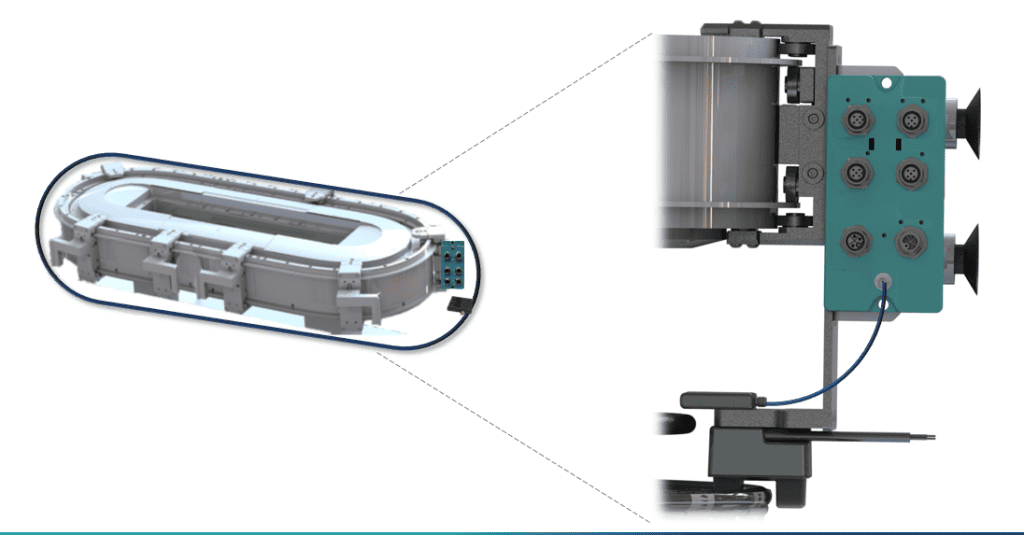

Innovative Machine Design

CoreTigo’s solutions are creating new opportunities for machine builders in the deign and development of innovative machines. The elimination of wired communication constraints enables machines to be much more flexible and adaptive without needing to tradeoff capacity and throughput. Machine builders can now wirelessly control and monitor any fast moving or rotating component, and leverage IO-Link Wireless both for new machine designs and for retrofitting existing machines.

"The combination of the flexible electromagnetic product transport module we used in the customer machine and the CoreTigo technology, results in a minimal footprint and makes the line much more flexible. I’m sure, we will have many more opportunities to expand our collaboration in the future."

Andreas Graf

CEO

"We wanted to have communication that was at least as reliable as cable communication... Together with CoreTigo we had an amazing journey. For us IO-Link Wireless is the next step of creating smart machinery for the future of packaging machines, helping us to go the extra mile.

Manu Peelman

Principal Technical Program Manager

Intelligent Wireless Automation Solutions

Automation equipment manufacturers are leveraging CoreTigo’s technology and products to expand their product portfolio and enable intelligent wireless solutions. A broad range of sensor, actuator and I/O device providers are integrating IO-Link Wireless in a variety of products. These include grippers, pumps, valves, clamping systems, linear track systems, rotary tables, servo motors, IIOT Gateways, and more.

“For the factory automation wireless communication is required to ensure operator mobility, and that the generated data (control & monitoring) is integrated. We have seen the limitation of Wi-Fi, Bluetooth, ZigBee etc., and are now integrating IO-Link Wireless in our products".

Ashwani Singh, PhD

Global R&D Director at Telemecanique Sensors

Improving Operational Efficiency for Greenfield and Brownfield Deployments

System Integrators, solution providers and distributors worldwide are driving operational efficiency by leveraging CoreTigo’s wireless connectivity that is designed specifically for factory automation and its broad ecosystem of automation partners and integrated products. Simple and rapid machine and production line retrofit is enabled, along with complete visibility throughout the factory, even at hard-to-reach places or fast-moving components. Integration to a variety of on-premises and cloud-based applications is done easily and intuitively.

“CoreTigo’s technology helps us and our customers achieve new applications, intelligent solutions and increased flexibility. We are happy to provide the Japanese market with Industry 4.0 and IIoT advanced capabilities.”

Noby Fujiki

CTO

Industry 4.0 Communication Solutions on the Factory Floor

Mass customization, operational excellence and sustainability are fundamentally changing manufacturing. To compete, manufacturers need machines and production lines that are substantially more flexible, versatile, scalable, and cost-effective. Maximum adaptivity, along with higher throughput and downtime reduction are all common requirements as manufacturers advance towards Industry 4.0. CoreTigo’s solutions are breaking the limits for machine communication and enabling connectivity anywhere, in places that were not possible before, and creating adaptive, sustainable and more intelligent production lines.

"Moving towards the IIOT, the implementation of wireless sensors improves our monitoring quality, reduces manual operations and enables more frequent data capturing, thus boosting operational excellence and reducing risks. CoreTigo has been key for the success of this process."

Claudinei Marchetto Reche

President of LAM

IO-Link Wireless – From Wired to Wireless Factory Automation

A global wireless communication standard designed specifically for factory automation

Reliable

Cable-grade reliability, deterministic, coexists with other networks, immune to industrial environments

Fast

Low latency of 5 msec with ultra-high synchronization rates

Scalable

Supports a large number of devices while maintaining the required low latency and high reliability

Universal

Part of the IO-Link IEC standard designed for both wireless control and monitoring

Highlights

Emerson and CoreTigo Save Energy with Wireless Air Treatment Solution

Emerson and CoreTigo tackles improve Compressed Air Management in machinery, reducing energy waste and CO2 emissions, enhancing maintenance efficiency and operational processes.

Efficient Natural Stone Processing Machines with IO-Link Wireless

World-known manufacturer of natural stone processing plants and machines, Pedrini and CoreTigo enhance natural stone processing machinery.

Schmalz and CoreTigo Enhance Industrial Vacuum Automation

Schmalz, a field leader in vacuum automation and ergonomic handling solutions, and CoreTigo unbind robotic vacuum pumps for a variety of industrial applications.

CoreTigo Receives Investment from Amazon to Accelerate Industrial Connectivity

Amazon’s Industrial Innovation Fund joins CoreTigo’s strategic investors.

Rockwell Automation awards CoreTigo Technology Partner of The Year EMEA 2023

CoreTigo’s disruptive technology is used in customer applications which have enabled the complete transformation of how their products are produced.

The Adaptive Packaging Machine

Together with Rotzinger PharmaPack and additional partners from CoreTigo's ecosystem, we developed the Adaptive Packaging Machine.

The Benefits of the Industrial Internet of Things

From manufacturing and energy to transportation, wireless IIoT is driving innovation and unlocking new opportunities for businesses.

Emerson invests in CoreTigo to reach the full potential of Industry 4.0

Global technology and software leader Emerson joined CoreTigo’s portfolio of distinguished investors.

CoreTigo's products & solutions demonstrated live

Join us on various worldwide events throughout 2023 to see IO-Link Wireless in action.

Achieving Industry 4.0 Adaptability with IO-Link Wireless

A high degree of movement dynamics and flexibility are the success factors of modern machine concepts. deliver optimized production processes

AB InBev integrates IO-Link Wireless

World’s largest brewer, AB InBev Harnesses CoreTigo’s IO-Link Wireless Technology for Advanced Manufacturing Solutions.

IO-Link Wireless on Rockwell's iTRAK

Learn how machine builder Cloostermans integrated IO-Link Wireless solutions to extend the flexibility offered by Rockwell’s iTRAK® based packaging machine.

Working with Industry Experts